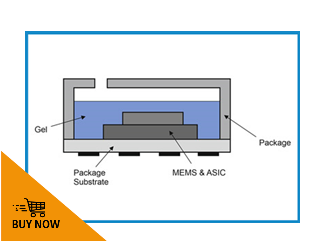

Smart watches and wearables are often used in harsh environments and its features like motion and activity tracking request highest precision, fast read-out and low power consumption. For accurate elevation gain, vertical speed and motion detection, they integrate barometric pressure sensors. The new DPS368 is ideal for these applications as it saves up to 80% space compared to other waterproof pressure sensors, offers a precision of +/-2cm and up to 50% power savings compared to piezo-resistive technology. The digital barometric air pressure sensor is robust against water, humidity and dust, as the pads and membranes are protected by gel (figure 1). It is IPx8 certified and can withstand 50m under water for one hour.

The pressure sensor element of the DPS368 uses a capacitive sensing principle which guarantees high precision during temperature changes. It is based on the proven DPS310, but with a very robust and waterproof package. This combination makes the DPS368 ideal for a variety of applications (figure 2) in harsh environments. Target applications are smart watches, wearables and smart phones (e.g. fitness tracking, step counting, fall detection, navigation, altitude detection); home appliances (e.g. air flow control in HVAC / vacuum cleaner, water level detection in washing machine, intruder detection); drones (e.g. flight stability, height control), and health care (e.g. fall detection, air flow monitoring).

Robust and sensitive

The Infineon DPS368 offers superior resolution, temperature stability, energy efficiency and high robustness. This combination of benefits makes it particularly attractive in battery powered applications where sensing of very small pressure changes is needed – even in harsh environments. The sensor integrates both barometric pressure and temperature sensing (figure 3) into a single, extremely compact 8-pin LGA package that measures just 2.0mm x 2.5mm x 1.1mm. Average current consumption is 1.7mA for pressure measurement (only 0.5mA in standby mode).

Capable of precision to +/-0.002hPa (equating to +/-2cm), the device can measure air pressure between 300hPa and 1200hPa at a temperature of -40 to 85°C and has a pressure temperature sensitivity of less than 0.5Pa/°C. The temperature accuracy is specified with ± 0.5°C. The sensor is able to detect single stairs, body motions or gestures. Every single component is individually calibrated during production with the calibration coefficients stored in one-time programmable (OTP) memory. Raw data can be transferred using an I2C or SPI interface, with compensated pressure values being calculated in the host device.

The device provides up to 50% less power consumption then competitor products when running in full speed due to its capacitive technology (AC biasing), which leads to longer battery lifetime. An integrated FIFO that can store 32 measurements and allows the host processor to remain in sleep mode for long periods between read provides further system power savings. The high measurement rate (up to 200Hz) and fast read-out enables a quick sensor feedback.

Capacitive technology

Typical small form factor MEMS (Micro Electro Mechanical System) pressure sensors are built around piezo-resistive measurement techniques. In these cases, the flexing of a diaphragm in relation to changes in pressure is sensed via a strain sensor. However, piezo-resistive sensing elements are particularly susceptible to variation with temperature changes and they do not respond linearly to temperature. For this reason, these sensors have a need for more complex calibration compared to a capacitive element. In addition, resistive measurement comes with a relatively high current consumption – a particularly important consideration when the target application is battery powered and operating lifetime is critical.

Because of the limitations of piezo-resistive technology, Infineon developed a capacitive MEMS technology for its pressure sensors. The cell structure and capacitive bridge configuration developed is illustrated in figure 4. The barometric pressure sensor consists of four arrays of sensing and reference cells. The sensing cells have a flexible membrane which reacts to pressure change and provides the air pressure measurement. The reference cells have a stiff membrane which does not react to pressure changes and provide a stable measurement reference. The benefit of this type of structure is that the pressure measurement can be differential and both sensing and reference cells are exposed to the same temperature changes negating temperature drift effects. The cell size is optimized for high sensitivity and mechanical reliability. Based on the small MEMS cell there is no gravity effect. Other key features besides the very good temperature stability over wide temperature and pressure ranges are low noise and low power consumption.