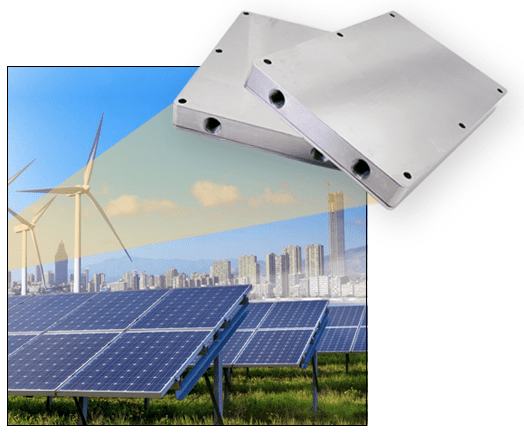

With today’s high-powered semiconductors and IGBT modules, air cooling is often an inadequate method of preventing a costly thermal breakdown. For cooling high-powered electronics, IGBT modules, lasers, wind turbines, motor devices, automotive components or medical equipment, engineers are looking to liquid cooling solutions and cold plates are a preferred method for supplying localized cooling to high-powered electronics.

By transferring heat from the device to a liquid that flows to a remote heat exchanger, the heat dissipates into either the ambient or to another liquid in a secondary cooling system. ATS (Advanced Thermal Systems) new ATS-CP Series of IGBT Liquid Cold Plates provide a uniquely high thermal performance because of their mini-channel fin design. The internal, mini-channel fin structure enhances the surface area to maximize heat transfer with low pressure drop characteristics and provides uniform cold plate surface temperature.

As such, the ATS-CP series of cold plates, at a flow rate of 4 L/min, can transfer 1kW of heat between 5.0°C to 7.0°C temperature difference between the cold plate base and inlet fluid temperature, depending on the model. This process improves thermal performance by more than 30% as compared to commercially available cold plates.

Customization is also available. ATS can design cold plates to meet size restrictions and manufacture cold plates to connect with a variety of components. The ATS Cold Plates are compatible with industry accepted coolants; for coolant with particles, #60 filters or finer are offered.