Solid tantalum capacitors offer infinitely useful lifetimes and unparalleled volumetric efficiency, making them a smart choice for high-reliability applications including military, aerospace, and medical devices.

Solid tantalum capacitors are among the most popular types of small, surface-mount capacitors for electronic applications across the consumer, automotive, aerospace, and medical device markets. This paper will provide some context on the development of tantalum capacitor technology and address issues frequently faced by users, including the need for low equivalent series resistance (ESR) in filtering applications and the need for the highest possible reliability and long-lifetime performance in aerospace and medical applications.

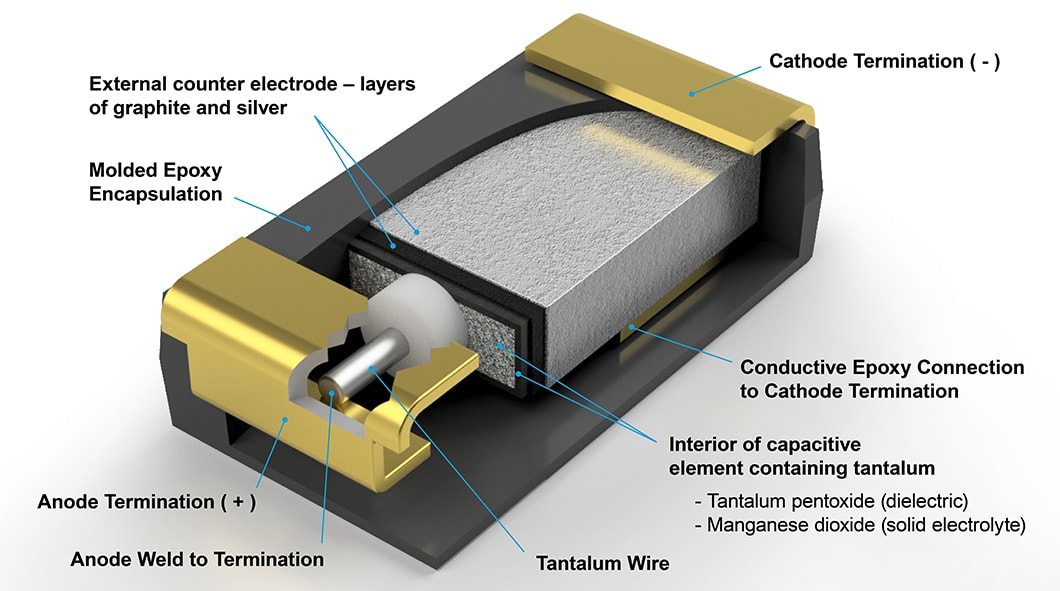

Solid tantalum capacitors are electrolytic capacitors, and all electrolytic capacitors are polar, meaning that current will only pass from the positive end (the anode) to the negative end (the cathode). The three major elements of an electrolytic capacitor are the anode, dielectric, and cathode. The tantalum anode consists of particles of very pure tantalum powder that are pressed and sintered into a sponge-like structure. Traditional versions have a tantalum wire embedded within the structure to create the positive connection to the circuit. The surface of the anode is covered with a layer of tantalum pentoxide (Ta2O5), which functions as the capacitor dielectric. In traditional solid tantalum capacitors, the cathode is manganese dioxide (MnO2). This material is deposited over the dielectric, followed by other materials — typically carbon and silver — to establish a connection with the other capacitor components.

A HISTORY OF TANTALUM CAPACITORS

The history of solid tantalum capacitors started in the 1950s when the concept was invented by Bell Labs to provide small capacitors to accompany their transistors. The structure of a tantalum capacitor is sponge-like, with a very high surface area available for dielectric formation. This provides high capacitance in a much smaller package than other capacitor technologies.

Over the course of the following decades, tantalum capacitor technology evolved to include several form factors. Axial- and radial-leaded configurations that are compatible with automated insertion processes for through-hole technology dominated until the 1980s. At that time, assembly technology evolved to embrace surface-mount technology (SMT) and SMT tantalum capacitors of various sizes were developed and widely adopted.

The widespread employment of surface-mount technology exposed tantalum capacitors to conditions outside of those experienced by their axial- and radial-leaded counterparts. High-temperature, board-level reflow processes can initiate defects in the thin-film dielectric layers of tantalum components, and can occasionally lead to catastrophic failure and even ignition.

As a result of this experience, tantalum capacitor manufacturers adopted in-line reflow conditioning and other measures to help the capacitors survive mounting and reflow conditions. These efforts have been successful at mitigating the risk of catastrophic failures, enabling solid tantalum capacitors to provide reliability that is suitable for any application.

Demand for tantalum capacitors grew dramatically with the development of reliable SMT versions in the late 1980s and continued into the 1990s. Surface-mount solid tantalums were the smallest capacitors in the 1–100μF range, and became the industry standard for many applications. The introduction of cellular phones and personal computers, along with the incorporation of extensive electronic equipment in automobiles, were the primary market drivers of this growth… continued in pdf at bottom of page

AVX are exhibiting at eBOM LIVE, to view their company profile and to seek more information please click the button below

To view the rest of this white paper please click the image to view the full pdf