Light pipes can be very useful for manufacturers in industries ranging from aircraft instrumentation to health care, as well as the devices we rely on to make our lives easier at home.

But first, what the heck are light pipes?

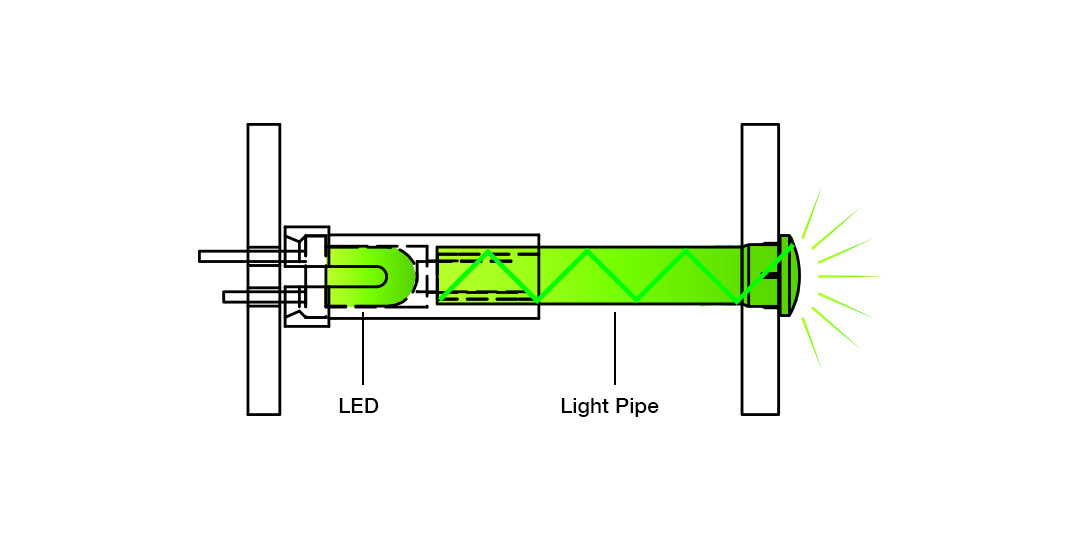

Light pipes are clear tubes that transmit light from a light source, such as an LED to a user interface. Designed to carry light short distances with high efficiency, light pipes can bend light around corners and tight spaces delivering excellent visual indication with minimal loss of light intensity.

How do light pipes work?

A light pipe is placed very closely to an LED light source on one end of a PCB board. Its optical-grade materials help carry the rays of light to the desired destination, typically at the user interface of a device.

Light pipes transmit roughly 80 to 90 percent of the light from the LED source, depending on design and spacing. The closer the light pipes are to the LED(s), the more efficiently they can transfer light.

Of course, the light pipe(s) used will need to be rated for the same amount of heat that is produced by the LED or light source, so that must be a design consideration as well that can dictate the minimum allowable distance between the light pipe and the light source.

Why use a light pipe?

Depending on the equipment and the design of the user interface of a device, a product can require more than one — and up to many — indicators. For designs that require multiple indicators, light pipes are an ideal solution due to their low cost, excellent visual communication and design flexibility.

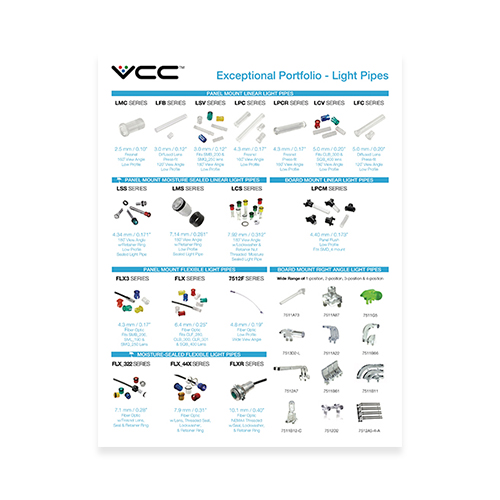

Light Pipe Brochure

Similar in name, but not the same: A quick lesson in illuminated component terminology

The term “light pipe” is often interchanged with “light guide.” To clear up some confusion, here’s a simple breakdown of all three lighting products:

Light pipe – the term “light pipe” can also be called a “light guide,” or “light tube.” To make things more confusing, they’re sometimes called “litepipes”, too. A light pipe is a rod made of optical acrylic or polycarbonate that transmits light from a light source, typically an LED, at the circuit board to the panel of the device. These light pipes are ideal for carrying the light in a small space, like a status indicator or control panel.

Light diffuser – light diffusers are used to spread light from an LED source over a defined area, but also reduce the brightness of the light it transmits. Therefore, light diffusers are typically made of opaque materials. Light diffusers can be used in conjunction with light pipes or light guides. They also increase the viewing angle and are ideal for soft illumination of defined areas.

Light diffuser – light diffusers are used to spread light from an LED source over a defined area, but also reduce the brightness of the light it transmits. Therefore, light diffusers are typically made of opaque materials. Light diffusers can be used in conjunction with light pipes or light guides. They also increase the viewing angle and are ideal for soft illumination of defined areas.

For this guide, we will be focusing on the fundamentals of LED light pipes, or litepipes, if you prefer that spelling.

Light pipe design principles: Let’s begin with the benefits

We touched on how beneficial light pipes can be — yet we can’t mention it enough. They deliver a host of benefits for designers and OEMs, such as:

• Greater flexibility and control over – by adjusting the length, angle and spacing, designers can get the exact visual indication and uniform light visibility they desire with the right light pipe design.

• Minimized light leaks – when excess light shines through a device without illuminating the indicator properly, it leads to wasted light and provides a poor user experience in the final device. By selecting the right light pipe and optimal placement between the LED and panel, it delivers optimal illumination without losing light.

• Easy installation – no matter the type of light pipe, the installation can be literally a snap with a snap fit or press-fit light pipe.

• Production efficiencies – when a device has multiple panel mount indicators (PMIs), the production costs can really add up. Light pipes are a great alternative that brings down the cost without skimping on reliability, design flexibility or visual indication.

• Easily customizable solutions – light simulations and ray tracing with advanced software helps design teams develop the ideal indication solution that can achieve all of the manufacturer’s goals

• Reliable, uniform performance – when combined with LEDs, light pipes of various lengths deliver a consistent and uniform illumination that can last the life of the device

• ESD protection – light pipes can prevent electrostatic discharge that can damage the device by isolating the PCB or circuit board from the user interface

Light pipes vary in more than just color

Like with any new product design, the decisions made early in the process can shape some of the constraints that must be accommodated later in the process, from the size of the PCB to the amount of space on a panel. These decisions may not seem like that big a deal, but when light indication or user interface decisions are made early-on, the manufacturers — and ultimately the end users — win.

Light pipes are available in a variety of styles and can suit a host of LED mounting options. To really maximize efficiencies in your product design, you need to know the pros and cons of the different types of light pipes.

They typically fall into two major categories: rigid and flexible.