SHENMAO Technology, Inc. announced plans to exhibit at the International Wafer-Level Packaging Conference, scheduled to take place Oct. 23-25, 2018 at the DoubleTree by Hilton San Jose in California. SHENMAO plans to showcase its new PF906-S and PF912-S solder alloys.

SHENMAO’s high thermal/drop reliability series solder alloys can be used in a wide range of solder applications. The alloys have a similar operating temperature window to Sn-Ag-Cu alloys, so that they can easily be adopted into existing packaging processes.

The PF906-S Sn/Ag4.0/Cu0.5/Bi3.0/Ni0.05 alloy has excellent thermal reliability and is designed for use in automotive electronic applications.

The PF912-S Sn/Ag2.0/Cu0.5/Bi3.0/Ni0.05 alloy has excellent thermal and impact reliability compared to conventional solder alloys such as SAC305 and SAC405.

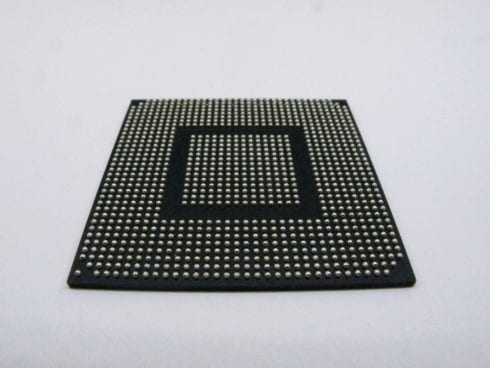

SHENMAO has successfully been approved by many international well-known electronic manufacturers. The company strives to offer the best quality without compromising cost and time-to-market while providing maximum value to all customers. As the world’s major solder materials provider, SHENMAO produces SMT solder paste, laser soldering paste, cored solder wire, wave solder bar, semiconductor packaging solder spheres, wafer bumping solder paste, flux and solar PV ribbon.

SHENMAO America, Inc. blends SMT solder paste at its facility in San Jose, CA for distribution in North America. For more information, please visit www.shenmao.com.

About SHENMAO

SHENMAO is dedicated to the production of solder products including Water Soluble and No-clean Solder Paste, Laser Solder Paste, Solder Preforms, Cored Solder Wire, Wave Solder Bar Alloys, Wave Soldering Fluxes, Extremely Pure Solder Powder up to Type 8, BGA and Micro BGA Solder Sphere, Wafer Level Packaging Solder Paste and Fluxes, LED Die Attach Paste, High Performance Liquid Fluxes, Solder Preform, Solar Ribbon, Plating Anode used in PCB Fabrication, Assembly and Semiconductor Packaging Processes.