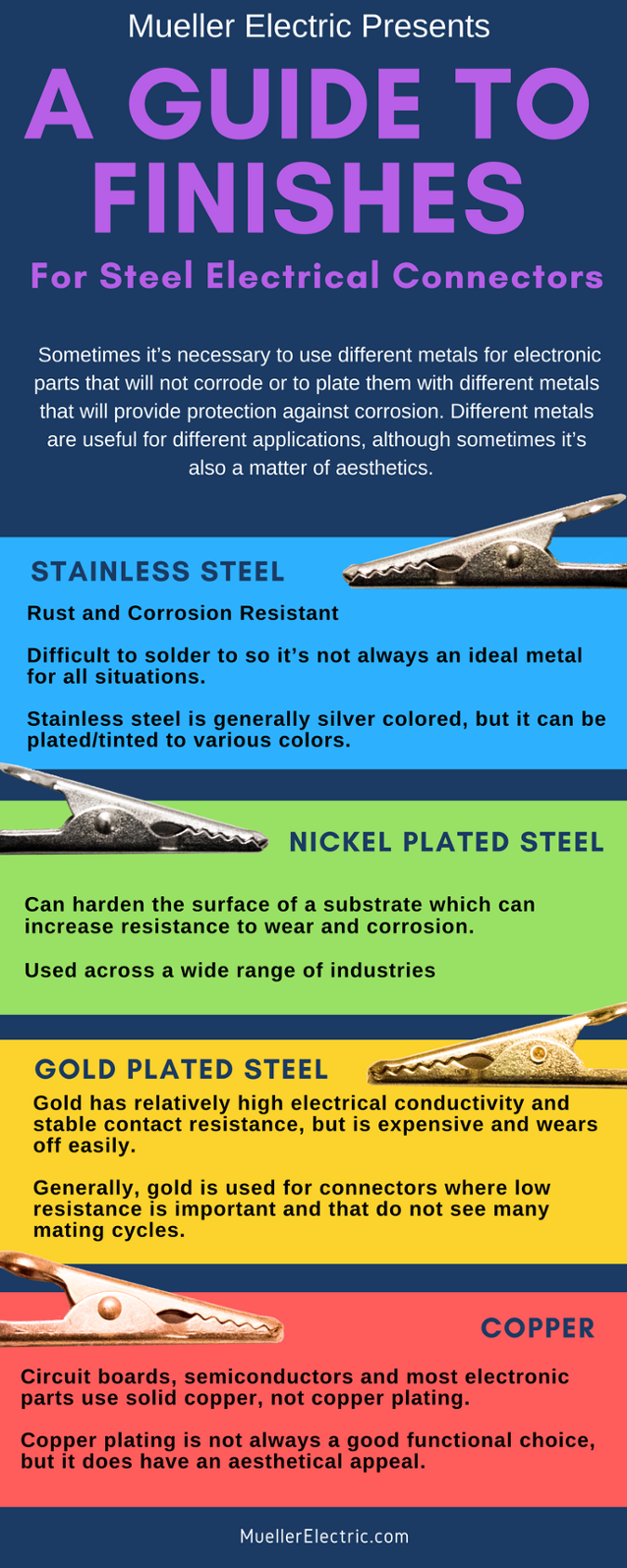

Stainless Steel

Stainless steel remains stainless – meaning it does not rust or corrode because of the interaction between its alloying elements and the environment. It forms its own film layer on the outside of the metal that protects itself from attack by the elements. The downside to stainless steel for electronic parts is that it is difficult to solder to so it’s not always an ideal metal for all situations.

Stainless steel is generally silver coloured but it can be plated/tinted to various colours.

Gold Plated Steel

Gold has relatively high electrical conductivity and stable contact resistance. It is one of the most conductive of all metals.

Electroplating gold increases the substrates resistance to corrosion. Gold is the most nonreactive of all metals. Gold will generally not rust/oxidize in the outdoor elements. Due to cost, gold is normally plated very thin on connectors. This along with gold being so soft, allows it to wear off from the connector rather easily which exposes bare steel. Also, if the connector is used to connect or disconnect a live circuit above an amp or so, then the plating will burn off the contact area in a short time. Generally, gold is used for connectors where low resistance is important and that do not see many mating cycles.

All of these factors makes gold plating a popular choice for electrical components such as semiconductors and connectors. The downside to gold plated parts is the cost, as gold is not an inexpensive material. It is also soft and easy to wear/burn off.

Nickel Plated

Nickel plating provides a bright finish and can harden the surface of a substrate which can increase resistance to wear and corrosion. There are different types of nickel finishes that can range from dull silver to bright and shiny to black. Nickel’s corrosion protection is used across a wide range of industries including heavy equipment, oil & gas, power transmission & distribution, automotive, and marine.

Copper Plated Steel

Copper is an excellent conductor of electricity. All-copper and copper electroplating is a preferred metal finishing choice in the manufacturing of electronic circuit boards, semiconductors, and other electronic parts and components. Copper is an excellent conductor of electricity. All-copper and copper electroplating is a preferred metal finishing choice in the manufacturing of electronic circuit boards, semiconductors, and other electronic parts and components. Circuit boards, semiconductors and most electronic parts use solid copper, not copper plating. Copper plating is not always a good functional choice, but it does have an aesthetical appeal.