We are pleased to announce the release of two new NEMA 24 frame integrated motors with dual-port communications. The SWM24IP-3DE Integrated Stepper and TXM24IP-1DG StepSERVO™ Integrated Motor provide two M12 connectors for connecting to the industrial Ethernet network of your plant or machine. The ability to have two connectors on each axis instead of just one permits more efficient network topologies such as line networks and daisy-chain connections.

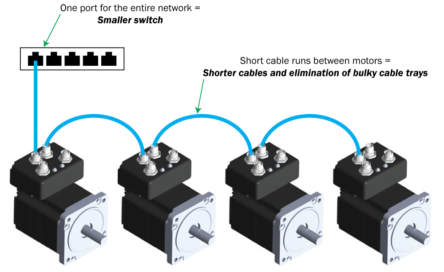

The small but important improvement of an additional communications port allows for cost savings and design simplification via the reduction of cable lengths, the omission of bulky cable runs, and the downsizing of network switches. In a star network every single motor must connect to the central switch on a dedicated cable. In a line network, the motor furthest from the switch can connect directly to its nearest neighbor motor, which in turn can connect to its nearest neighbor, and so on all the way back to the switch. The diagram below shows how this works using 4 integrated motors. Imagine what this would look like with 10 or 20 motors.

The SWM24IP-3DE and TXM24IP-1DG are IP65 rated for use in splash zone and dirty environments. Each motor features a NEMA 24 (60 mm) mounting flange which has the same mounting dimensions as a NEMA 23 motor but with a larger shaft to accommodate the higher torque output. Both motors include a built-in encoder for enhanced positioning capabilities, while the TXM24IP-1DG utilizes our StepSERVO™ Closed-Loop Stepper Technology to greatly improve the performance of the step motor in numerous ways.